Summa S Class Vinyl Cutters

The S Class is undisputed when it comes to professional cutting plotters: they are equipped with the latest technologies. The S Class uses an outstanding sensor technology and complex algorithms to compensate any deformation.

S Class cutters are excellent film and contour cutting machines, ideal for volume production. The S Class series is available in four widths, and you have a choice of two models:

• T-series: tangential head

• D-series: drag knife cutter

For any kind of job or material we have the right type of cutter and knife. We encourage you to read the brochure for more information!

Clear controls

The new color touch control panel has become even easier to use!

The bright colors and the new design of the menu structure ensure easier and faster navigation.

Frequently used operations such as cut off media, adjust knife pressure, adjust offset, change user profile, are all adjusted in an instant.

&

USB & Ethernet LAN connection

USB port

As usual, you can control your computer using the supplied USB cable.

USB Memory Stick interface

Put your frequently used plot jobs on a USB drive and you can access them from the menu. This allows you to work even faster.

Ethernet LAN port

More flexible communication than before! You can now send your plot jobs from multiple computers to an S Class 2 plotter.

Can also be used with a network crossover cable for a direct Ethernet connection between the computer and plotter.

7 times faster processor

An entirely new processor that is seven times faster than the previous generation S Class!

The new processor shortens the amount of time needed for processing which means you have more opportunity to output more jobs throughout the day.

This processor upgrade also provides the added benefit of faster USB communication, which contributes to the overall processing of your orders.

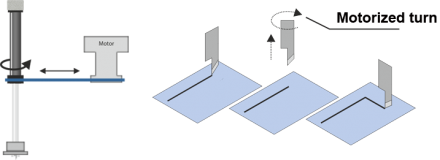

Tangential cutting technology

Tangential cutting technology guarantees a superior performance compared to commonly used swivel knife techniques. The direction of the tangential knife is electronically controlled, by which T series are capable of cutting very precisely and with very high pressures.

The perfect cutting makes weeding very easy, saving you a lot of valuable time. The patented nose piece avoids small pieces being pushed out of the vinyl while cutting.

With up to 600 grams of cutting force, Summa S Class T series powers through heavy sandblast, paint mask and reflective materials with incredible ease, speed and accuracy. With a T model, you know you can do the job!

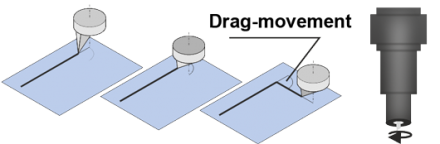

Drag knife technology

Its simplicity has made drag knife (or swivel knife) technology the most commonly used. An offset parameter defines the distance between the knife tip and the rotating centre. In order to know the position of the freely rotating knife inside the knife holder a drag movement is made assuming the knife tip will follow accordingly.

Summa cutters include enhanced methods to optimise this drag-movement to obtain the best possible cutting quality.

OPOS CAMera Contour cutting

With OPOS-CAM, Summa delivers yet another amazing innovation with the printing industry’s first camera recognition alignment solution for friction driven vinyl drum cutters. Summa customers in volume driven workflow environments will now be able to excel against their competition with super fast precision, accurate cutting of short or long run contour cutting jobs.

OPOS-CAM is a factory upgrade option now available on all new Summa S Class T-series vinyl cutting plotters.

Automatic cut-off after job

The S Class cutting heads have an auto cut-off knife, which you can optionally set to slice your media at the end of each job. The finished jobs fall neatly into the canvas basket to keep them free of dust.

Because you don’t have to manually cut off the media at the end of each job, you save valuable seconds, job after job.

Optional: Automatic roll-up system

After a job is finished, the system will roll up the artwork very neatly and prepare the machine for the next unattended job. The integrated panelling feature splits long-length runs in shorter consecutive jobs!

The S Class can therefore cut complete rolls unattended and delivers the output nicely rolled-up. The roll-up system is available as option for the S140 & S160 models.

Optional: Media rack

A solid and most effective media rack to store three or more media rolls on the back of the plotter. It is advisable to purchase extra flanges for these extra media rolls, for proper storage.

The media rack is available for the S140 and S160 models.

Summa S Class models

Available in four widths, including Stand and Basket. Each model is available in two models: tangential head (T) or with a drag knife cutting head (D).

Upgrades/options: OPOS-CAM is available for all models. For the S140 and S160 models there is a media rack and roll-up system available.

S75D / S75T

74,2cm

S120D / S120T

120cm

S140D / S140T

135cm

S160D / S160T

158cm

Quickly create your own:

Explore the Summa S-Class 2 brochure

Specifications

Plot Speed

Max 1410mm/s diagonal

Mechanical Precision

0,2% or 0,25mm

Cutting Width

Up to 158 cm

Plot Length

Up to 50 meter

Plotter

Plot speed

Maximum 1410mm/s

Plot length

Maximum 50.000mm (50m)

Max. media width

S75: 6 to 84cm

S120: 12 to 130cm

S140: 17 to 145cm

S160: 17 to 168cm

Cutting range width:

S75: 74,2cm

S120: 120cm

S140: 135cm

S160: 158cm

Cutting range width (oversized mode):

S75: 81,2cm

S120: 127cm

S140: 142cm

S160: 165cm

Acceleration

Up to 5,5G diagonal

Knife pressure

Drag knife: 0-400g, adjustable per 5 grams

Tangential: 0-600g, adjustable per 5 grams

Mechanical precision

0,2% or 0,25mm (highest value counts)

Repeating precision (guaranteed)

0.1mm 12m on rolls with max width 76cm

0.1mm 4m on rolls wider than 76cm

Connections

USB, Ethernet LAN

Sizes including stand

S75: 100 x 68 x 112cm (b x d x h)

S120: 160 x 68 x 112cm (b x d x h)

S140: 175 x 68 x 115cm (b x d x h)

S160: 198 x 68 x 115cm (b x d x h)

Power

Ingangsspanning

110-230V, 50Hz/60Hz

Additional

Relative temperature

5°C – 40°C

Relative air humidity

25% – 85%, non-condensing

Storage temperature

-40°C – 60°C

Storage air humidity

10% – 90%, non-condensing

Ventilation

Free air

Certification

CE, RoHS, WEEE

Supplies

Quality

The adhesive films are produced under the UNI EN ISO 9001-mark, which is a sign of quality and prestige, gained through the constant improvement of production processes.

The factory also has the environmental certificate UNI EN ISO 14001 to emphasize the commitment to protect our environment.

Vinyl rolls

Easy vinyl

Self-adhesive vinyl for indoor and outdoor usage, perfect for the decoration of showcases, displays, panels / plates for short-term use and exhibition stands. Shelf-life of 3 years outdoors. Glue: acrylic semi-permanent with high adhesiveness. Vinyl thickness: 80 micron. Available colors: 25 glossy, 33 matte.

Elite vinyl

Self-adhesive vinyl for the decoration of shop windows, billboards, cars, exhibitions and for all outdoor medium-lasting applications on flat surfaces. Shelf-life for outdoor use for 5 years. Metallized colors 3/4 years. Glue: eco-acrylic permanent with high adhesiveness. Vinyl thickness: 75 micron. Available colors: 59 glossy, 51 matte.

Cast vinyl

High quality adhesive cast film for the decoration of cars, ships, aircrafts, containers and signs. Pliable and flexible on bent and riveted surfaces. Wet method can be used as well. Shelf-life of 8-10 years outdoors. Metallized colors will last 5 years. Glue: acrylic, ultra permanent, extra adhesive. Vinyl thickness: 55 micron, C/967 90 microns. Available colors: 86 glossy, 2 matte and one carbon-like.

Application tape

Types

Paper, light yellow – Low adhesive: easily apply your signs with our application tape.

Length

100 meters

Widths

50mm, 100mm, 150mm, 200mm, 280mm, 300mm, 350mm, 450mm and 610mm

Software for your vinyl cutter

See all of the possibilities!

FlexiSIGN software

Design and Production from A to Z, no need for extra software.Complete package

SAi Flexi is the only all-in-one design, print and cut software for sign and print providers.

With nearly 3 out of 4 shops using it, Flexi is the industry-standard for sign-specific design tools, RIP and print, print-and-cut, and direct vinyl cutting.

Do you want to see all of the features? See our FlexiSIGN page!

WinPlot / MacSign Cut & your own design software

Software that lets you send jobs to your cutter from your existing software.Free software!

WinPlot for Windows and MacSign Cut for Apple OS X are supplied free with your Summa cutter!With this software you can send your own design file (EPS) to your vinyl cutter.

You can easily control the number of copies, desired dimensions and all other cutter settings.

You can not change the design in WinPlot / MacSign Cut. You would need to do this using your existing design software, such as Adobe Illustrator or Corel Draw. Or use the free open source design software Inkscape.

Don’t hesitate to contact us incase you have any questions or if you would you like some advice.

EasySIGN software

Design and Production from A to Z, no need for extra software.Complete package

EasySIGN is een compleet ontwerp-, snij- & print pakket voor signs.Ontwerp uw eigen sign en verstuur deze direct vanuit EasySIGN naar de plotter. Ook print & cut printers zoals Summa, Roland, Ricoh, OKI zijn ondersteund. Vele beletteringsbedrijven hebben deze software in gebruik.

Ook heeft EasySIGN plugins voor Adobe Photoshop, Illustrator en CorelDRAW, waarmee u tevens vanuit die software kunt produceren.

Do you want to see all of the EasySIGN features? Have a look at our EasySIGN page!

Summa qualities

Watch the Summa S Class videos!

And be amazed by the quality

Summa OPOS-CAM

S Class 2 with Roll up

Downloads

Meet the Summa S Class!

A non-binding demonstration?

More information here!An introduction with no obligations

Our sales representative will give you a free demonstration at our office.

This allows you to get familiar with the system, the use and its benefits.

Fill in the form below and we will contact you!

Do you have any questions or comments? Please fill in your details below.

Please select a valid form